Introduction

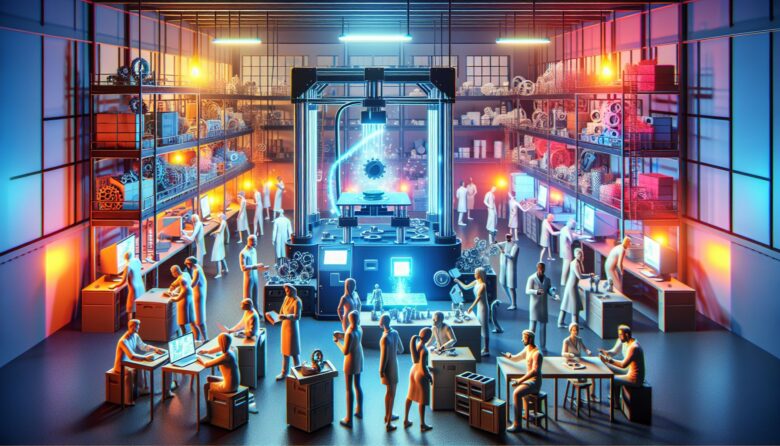

In recent years, we have witnessed a groundbreaking technological revolution that has transformed various industries, and one of the most significant advancements has been in the field of printing. While traditional printing methods have evolved tremendously over the years, the advent of 3D printing has revolutionized the manufacturing industry, allowing for incredible innovation and creativity. This blog post delves into the marvelous world of 3D printing, exploring its capabilities, applications, and impact on various sectors.

Body

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from digital designs. Unlike traditional printing, which produces two-dimensional images, 3D printers build objects layer by layer, using a variety of materials such as plastic, metal, and even organic compounds. This innovative technology allows for the production of complex structures that were previously impossible or costly to manufacture.

The Evolution of 3D Printing

The concept of 3D printing traces its roots back to the 1980s when Charles Hull invented stereolithography, the first successful 3D printing technique. However, the technology was limited to industrial applications due to its high cost, complexity, and size. Over time, advancements and research brought down the cost, improved the precision, and increased the accessibility of 3D printing, leading to its wider adoption in various fields.

Applications of 3D Printing

- Industrial Manufacturing: The manufacturing industry has witnessed a significant transformation with the implementation of 3D printing. It allows manufacturers to create prototypes at a fraction of the cost and time required by traditional manufacturing processes. Companies can now test and modify designs with ease, leading to faster product development and improved efficiency.

- Medicine and Healthcare: 3D printing has revolutionized the healthcare industry by enabling the production of customized medical devices, prosthetics, and implants. Surgeons can now plan complex surgeries by examining detailed 3D models of an individual’s anatomy, improving surgical precision and patient outcomes. Additionally, the production of pharmaceuticals and tissue engineering have also experienced remarkable advancements through 3D printing.

- Education and Research: 3D printing has found its way into classrooms and research labs, empowering students and researchers to bring their ideas to life. Educational institutions utilize 3D printers as powerful teaching tools, allowing students to visualize concepts and designs in a tangible way. Furthermore, researchers are leveraging 3D printing to fabricate models and prototypes that aid in their investigations and experiments.

- Architecture and Construction: Architects and engineers can now transform digital designs into physical models quickly and accurately using 3D printing. This enables them to evaluate design concepts and present their ideas more effectively. Additionally, in the construction sector, 3D printing has the potential to revolutionize the building process by enabling the construction of complex structures with reduced production time and cost.

Advantages of 3D Printing

The rise of 3D printing offers numerous advantages, making it a preferred manufacturing technique in various industries:

- Design Freedom: Traditional manufacturing methods often impose limitations on the shape and complexity of objects. 3D printing eliminates such constraints, enabling the production of intricate and personalized designs.

- Cost-Effective: Unlike traditional manufacturing, 3D printing entails minimal setup and tooling costs, making it economical for both prototyping and small-scale production. This cost advantage encourages innovation and entrepreneurship.

- Sustainability: 3D printing reduces material waste as it only uses the exact amount of raw material required for production. Additionally, the ability to recycle and reuse certain materials further contributes to a more sustainable manufacturing process.

- Rapid Prototyping: With 3D printing, companies can rapidly iterate designs and produce prototypes in a matter of hours or days. This rapid prototyping reduces time-to-market and allows for quicker product development cycles.

- Customization and Personalization: From customized medical implants to tailor-made consumer products, 3D printing enables mass customization on a scale never seen before. Personalized objects cater to individual needs, leading to improved user satisfaction.

The Future of 3D Printing

The potential of 3D printing is vast, and its impact on multiple industries is set to expand further in the future. Here are a few areas where the technology is expected to make significant strides:

- Aerospace and Automotive Manufacturing: The aerospace and automotive industries continually push the boundaries of engineering and design. 3D printing is poised to become an integral part of their manufacturing processes, allowing for the production of lighter, stronger, and more complex components. This will improve fuel efficiency and performance, driving technological advancements in these sectors.

- Food Printing: Culinary enthusiasts are eagerly exploring the possibilities of 3D printing in the food industry. From intricately designed chocolates to personalized nutrition, the ability to print edible objects opens up new avenues for creativity and efficient food production.

- Space Exploration: 3D printing has already found applications in space missions, where the ability to manufacture tools, equipment, and spare parts on-demand is crucial. As we venture further into space exploration, 3D printing will play a fundamental role in sustaining human presence and reducing reliance on Earth for supplies.

- Regenerative Medicine: The field of regenerative medicine aims to restore or replace damaged tissues and organs. 3D printing offers the potential to fabricate personalized and functional organs using a patient’s cells, reducing the risks associated with organ transplantation and long waiting lists for donors.

Conclusion

The emergence of 3D printing has truly revolutionized the world of manufacturing by breaking barriers and unleashing unparalleled creativity. Its transformative impact can be observed across various sectors, from industrial manufacturing and healthcare to education and construction. With its numerous advantages and the continuous advancements in technology, 3D printing is undeniably the future of manufacturing. As this innovative technology expands its horizons, we can only begin to imagine the incredible possibilities it holds for the years to come.