Printing is the reproduction of text and images using ink or substances on various surfaces. Its purpose is to create multiple copies of documents, images, or marketing materials quickly and efficiently. Information can be easily shared through printing. Ink or substances are transferred onto a printing surface to recreate the text or image. Different methods, such as inkjet printing, digital printing, or screen printing, can be used. Each method offers unique advantages for different projects. Printing can be done on paper, fabric, plastic, glass, and more. It allows for high-quality and vibrant images or text, making it ideal for marketing materials, signage, labels, and other printed products. Printing is essential in our daily lives, from personalized business cards to large-scale commercial projects. It enables mass production, making information more accessible and promoting effective communication.

Different Types of Equipment Used in the Printing Industry

Introduction: The printing industry relies on various types of equipment to produce high-quality prints on a wide range of materials. From inkjet printers to digital printing equip large-volume means, each piece of equipment offers its unique capabilities and advantages. In this article, we will explore the different types of equipment used in the printing industry, their features, and the types of projects they are best suited for. Whether you need to print marketing materials, labels, signage, or any other printed products, understanding the various types of equipment available can help you make informed decisions to achieve the desired results efficiently and cost-effectively.

Inkjet Printers

Inkjet printers are widely used in various industries due to their high resolution and advanced technology features, making them suitable for professional use. These printers utilize a technology that sprays tiny droplets of ink onto the printing surface, resulting in crisp and vibrant images.

When comparing basic office inkjet printers to commercial-grade inkjet printers, the main difference lies in their output capabilities. Commercial-grade inkjet printers are designed to handle large volume printing and are ideal for producing colored illustrations for reports and presentations. They offer faster printing speeds and are capable of handling heavier print media, making them a popular choice for businesses and professionals requiring high-quality prints.

One of the advantages of inkjet printers is their ability to produce high-resolution prints, providing unparalleled quality and sharpness. They are also equipped with advanced technology features such as wireless connectivity, touchscreens, and mobile printing options, enhancing efficiency and productivity.

However, it’s important to note that inkjet printers may have longer printing times compared to basic inkjet printers. Additionally, the cost of ink cartridges can be higher, especially for printers designed for professional use.

Inkjet printers are versatile and provide high-resolution prints, making them suitable for professional use. Commercial-grade inkjet printers offer higher output capabilities and are ideal for businesses requiring colored illustrations. Despite longer printing times and potentially higher ink costs, inkjet printers remain a popular choice for those seeking high-quality prints.

Digital Printing Equipment

Digital printing equipment has revolutionized the printing industry by providing cost-effective and high-quality printing solutions. This technology has replaced traditional printing methods, enabling businesses to meet their printing needs efficiently and effectively.

There are various types of digital printing equipment available in the market. One such machine is the Xerox 1000i digital press. This cutting-edge equipment offers exceptional print quality, ensuring vibrant and sharp images. With advanced features like variable data printing, it allows businesses to personalize their marketing material, enhancing their brand image.

The Xerox 1000i digital press also offers unmatched speed, capable of printing up to 100 pages per minute. This high productivity is vital for businesses with large-volume printing requirements. Additionally, it supports a wide range of paper sizes and weights, offering flexibility for diverse printing projects.

The cost-effectiveness of digital printing equipment, such as the Xerox 1000i, is another significant advantage. It eliminates the need for printing plates, reducing setup costs. Moreover, digital printing allows for on-demand printing, minimizing waste and storage costs.

Screen Printing Machines

Screen printing machines are widely used in the printing industry to create high-quality prints on various materials. There are different types of screen printing machines available, including flatbed systems and cylinder systems.

Flat bed screen printing machines are commonly used for printing on flat surfaces, such as paper, glass, and plastics. They feature a stationary flatbed where the material is placed, and the screen moves across it to apply the ink. These machines offer precise and consistent results, making them ideal for printing marketing materials and packaging.

Cylinder screen printing machines, on the other hand, are designed for printing on cylindrical objects like bottles and tubes. The material rotates on a cylinder, while the screen moves along it to transfer the ink. These machines allow for seamless printing on curved surfaces, ensuring high-quality and vibrant prints.

Both types of screen printing machines offer adjustable printing speed and length, allowing for customization and flexibility. This feature is especially valuable for meeting different production requirements and ensuring optimal print quality.

In addition to their core functionalities, screen printing lines can be enhanced with additional features. These may include slitters for cutting the printed material into desired sizes, dryers for drying the ink quickly, laminators for adding protective coatings, and die cutters for creating intricate shapes. These additional features further improve the efficiency and versatility of screen printing machines.

Overall, screen printing machines, whether flatbed or cylinder systems, offer unparalleled quality and versatility in printing on various materials. By incorporating adjustable speed and length, as well as additional features, these machines provide cost-effective and fine printing solutions for a wide range of projects.

Pad Printing Machines

Pad printing machines are versatile and efficient printing equipment commonly used for printing on various surfaces, including cardboard for packaging. These machines utilize a silicone pad to transfer ink from an etched plate to the desired object.

One of the key features of pad printing machines is their ability to print highly detailed and colored illustrations on different materials. They can produce vibrant and precise prints, making them suitable for professional use in industries such as manufacturing, promotional products, and electronics.

Pad printing machines offer several benefits that make them a popular choice. Firstly, they provide excellent registration and repeatability, ensuring consistent and high-quality printing results. Secondly, they can print on uneven or irregular surfaces, allowing for greater flexibility in design and product customization. Additionally, these machines are cost-effective and offer fast setup times, making them efficient for both small and large-volume printing projects.

When it comes to printing on cardboard, pad printing machines are particularly useful. The soft silicone pad enables the ink to adhere evenly to the cardboard surface, ensuring clear and sharp prints. Whether it’s logos, graphics, or product information, pad printing machines deliver exceptional results on cardboard packaging.

Variable Data Printers

Variable data printers play a crucial role in the printing industry, especially for customization purposes. These printers enable businesses to personalize their printed materials, whether it be direct mail campaigns, promotional materials, or event invitations.

Variable data printing, also known as VDP, is a digital printing technique that allows for the customization of each printed piece. It works by merging a database of unique information with a design template. This means that each printed piece can contain different content, such as names, addresses, images, and even specific offers or messages tailored to the recipient.

The benefits of variable data printing for marketers and businesses are significant. Firstly, it enhances customer engagement by creating personalized and relevant communication. By addressing recipients by their names and tailoring the content to their specific interests or preferences, businesses can establish a deeper connection and increase the chances of a favorable response.

Secondly, variable data printing enables businesses to streamline their marketing efforts by sending targeted messages to specific segments of their audience. This ensures that the right message reaches the right person, increasing the overall effectiveness of the campaign.

Overall, variable data printers provide a powerful tool for customization and individualization in the printing industry. They empower businesses to create highly personalized marketing materials that capture the attention and interest of their target audience.

Automatic Screen Printing Machines

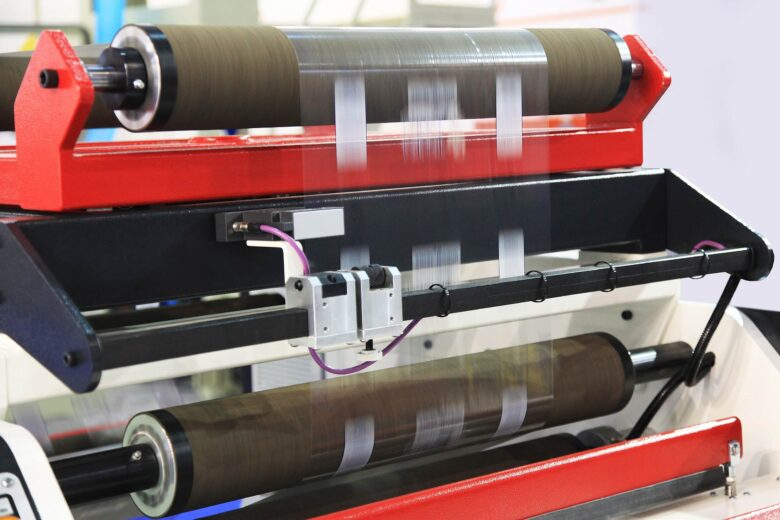

Automatic screen printing machines are a valuable tool in the printing industry, known for their ability to handle large-format work and achieve maximum efficiency. These machines are designed to streamline the screen printing process, allowing for quick printing of high-quality designs on a variety of products.

One of the key advantages of automatic screen printing machines is their dynamic web positioning feature. This means that the material being printed on is held in place by the machine, ensuring precise and accurate placement of the design. Whether it’s printing on fabric, paper, or other flat surfaces, these machines ensure that the design is aligned and centered perfectly every time.

In addition, automatic screen printing machines offer pneumatic push button controls for adjusting printing speed and length. This allows operators to easily control the printing process and make quick adjustments as needed. With just the press of a button, the speed and length of the print can be modified, ensuring optimal results.

Overall, automatic screen printing machines are a cost-effective and efficient solution for businesses in the screen printing industry. They provide unparalleled quality and ensure consistent and precise printing on a wide range of products. With their dynamic web positioning and pneumatic push button controls, these machines offer a reliable and user-friendly experience for screen printing businesses, taking their printing capabilities to new heights.

Commonly Used Techniques and Materials in the Industry

The printing industry is known for its wide range of techniques and materials used to produce high-quality prints. One commonly used technique is inkjet printing, which uses ink droplets to create vibrant, full-color prints. This method is commonly used in commercial printing and is known for its speed and efficiency. Another popular technique is screen printing, which involves using a mesh screen to transfer ink onto a printing surface. This method is commonly used to print on fabric and is known for its versatility and durability. Water-based inks are often used in screen printing, as they offer vibrant colors and eco-friendly properties. Additionally, digital printing has become increasingly popular, as it allows for variable data printing and fast turnaround times. Laser printers are commonly used in this technique, providing sharp and precise prints. Regardless of the technique used, the printing industry offers a wide variety of materials, including rolls of paper, sheets of paper, inkjet film, and photopolymer plates. These materials are chosen based on the specific requirements of each printing project, ensuring unparalleled quality and stunning results.

Quality Products & Water-Based Inks

Quality products and the use of water-based inks play a crucial role in the printing industry. These factors greatly impact the overall print outcome and customer satisfaction.

First and foremost, quality products are essential to ensure that the printed materials meet the highest standards. Whether it’s marketing materials, signage, or packaging, using high-quality printing equipment guarantees exceptional results. It ensures that the colors are vibrant, the images are sharp, and the final product looks professional.

In addition, using water-based inks provides numerous benefits. These inks offer vibrant and eye-catching colors that can enhance the visual appeal of any print. They also have the advantage of being eco-friendly since they contain fewer VOCs (volatile organic compounds) compared to solvent-based inks. This makes them a more sustainable choice for environmentally-conscious printers.

Furthermore, water-based inks are known for their durability. They adhere well to various substrates, including paper, fabric, and plastic, ensuring that the prints withstand wear and tear. This is especially important for products that are handled frequently, such as promotional items or clothing.

By choosing quality products and employing water-based inks, print shops, and businesses can deliver unparalleled quality to their customers. These choices not only yield visually stunning results but also contribute to a more sustainable printing industry. So, for those looking for a combination of vibrant colors, eco-friendliness, and durability, opting for quality products and water-based inks is the way to go.

Rolls of Paper & Flat Surfaces

In the printing industry, rolls of paper and flat surfaces are commonly used to produce a wide variety of print materials. Rolls of paper come in different sizes and weights, allowing printers to choose the most suitable option for their specific project. This includes large format printers that use wide rolls for banners and posters, as well as smaller rolls for labels and stickers.

When it comes to paper types, coated and uncoated are the two main options. Coated paper has a glossy or matte finish and is commonly used for high-quality prints, such as brochures or catalogs. The coating enhances the color vibrancy and sharpness, resulting in professional-looking prints. On the other hand, uncoated paper is more porous and has a rougher texture, making it ideal for projects that require a more natural and tactile feel, such as letterheads or envelopes.

Flat surfaces, such as garments and promotional items, are also popular choices for printing. Garments, including t-shirts, hoodies, and caps, can be printed using various techniques such as screen printing or direct-to-garment printing. Promotional items like pens, mugs, and tote bags can be customized with logos or designs using specialized printing equipment.

Common Applications for Different Types of Printer and Techniques

The printing industry offers a wide range of equipment and techniques to cater to different printing needs. Whether it’s inkjet printers for high-quality marketing materials, screen printing for durable and precise prints on garments, digital printing for personalized products, or laser printers for fast and efficient document printing, there is a printer and technique available for every printing requirement.

Commercial Printings & Digital Printings

Commercial Printing refers to the traditional method of printing that involves using printing plates to transfer ink onto various materials. It offers a wide range of functionalities and benefits. Commercial Printing is known for its versatility and ability to handle high-volume printing tasks efficiently. It is commonly used for producing marketing materials, such as brochures, flyers, catalogs, and business cards. The print quality of Commercial Printing is excellent, with vibrant colors and sharp details. It is also cost-effective for large-scale printing projects.

On the other hand, Digital Printing is a modern printing method that utilizes digital files to directly print images onto different surfaces. Unlike Commercial Printing, Digital Printing does not require printing plates, making it more efficient and cost-effective for small to medium-sized print runs. Digital Printing offers various benefits, such as quick turnaround time, variable data printing capabilities, and high color accuracy. It is commonly used for personalized products, such as wedding invitations, promotional items, and custom merchandise.

The key difference between Commercial Printing and Digital Printing lies in their technologies. Commercial Printing uses printing plates and ink rollers, while Digital Printing uses computer-controlled printers. Commercial Printing provides excellent color accuracy and a wide range of paper stocks and finishes. Digital Printing, on the other hand, offers quick turnaround time, variable data printing, and the ability to print on various substrates, such as fabrics, plastics, and metals.

Screen Printings for Businesses & Individuals

Screen printing is a popular printing technique used by both businesses and individuals across various industries. Its versatility and wide range of applications make it an ideal choice for creating high-quality prints on different materials.

In the textile industry, screen printing is commonly used for printing designs on fabrics such as t-shirts, hoodies, and bags. The graphics industry utilizes screen printing for producing posters, signage, and packaging materials.

Wide-format printing, which includes banners, billboards, and vehicle wraps, also heavily relies on screen printing. The automotive industry utilizes screen printing for decorative decals and emblems, while the electronics industry utilizes it for printing onto circuit boards and displays.

One of the primary benefits of screen printing is its ability to produce vibrant and high-quality prints. It can achieve vibrant and long-lasting colors, even on dark or transparent materials. Additionally, screen printing allows for precise placement and excellent detail, resulting in visually appealing prints.

Screen printing is highly versatile, as it can be used on various materials such as fabrics, plastics, metals, and glass. It provides businesses and individuals with the flexibility to create customized products, promotional items, and marketing materials.

Conclusion

In conclusion, the printing industry offers a wide range of equipment and techniques to cater to various printing needs. Screen printing is commonly used in the textiles and graphics industries, as well as in wide-format printing for banners and vehicle wraps. It is also utilized in the automotive and electronics industries for decorative decals and circuit boards.